ALLTERRA ARMS GIVES IT TO YOU STRAIGHT(ER)

A comment we hear most often is “I can build (or buy) a custom rifle that’s less expensive than yours.” While that certainly may be true ask if their rifle can do this:

- Shoot sub .5” 3-shot groups with premium factory ammunition

- Shoot sub .25” 3-shot groups with our custom ammunition

- Have no significant change in accuracy when shooting different bullet weights

- Will not fail to cycle in any field condition

We guarantee exactly that … and we put our money and reputation on it. We unconditionally guarantee your satisfaction. Shoot your AllTerra Arms rifle for 90 days and if it fails to perform to your expectations we will replace it or refund your money.

We know of no other guarantee in the industry that can make these claims. As they say, you get what you pay for and with AllTerra Arms you get the most accurate and reliable long-range rifle on the planet. Guaranteed. Here’s why:

AllTerra Arms builds rifles to .0005” tolerances using patented innovation design technology to achieve true Bolt-to-Bore Alignment™ and No-Fail Cycling™. The result is a rifle that literally transforms from a fast-action field gun to a precision bench rest rifle the moment a live cartridge is locked down. No other rifle in the world delivers bench rest accuracy and field reliability in a lightweight rifle. Check this out:

10 Reasons Why AllTerra Arms and Bolt-to-Bore Alignment™ earned the title of your “New Favorite Rifle”

- Revolutionary Patented Receiver

An AllTerra Arms receiver begins as an 8-pound pre-hardened 416 stainless steel round bar with a 2” diameter. This allows us to integrate the recoil lug right into the receiver. When the finished work of art is machined, it weighs in at less than a pound. Other gunmakers don’t like 7+ pounds of expensive waste steel, so they cut corners. We wouldn’t dream of it.

The others also drill to remove the center mass from the receiver, followed by broached raceways. The problem is, drill bits can “walk” away from the centerline of the receiver, and broaches lack concentric accuracy. This ultimately affects accuracy.

At AllTerra Arms, we only drill a small pilot hole through the center of the receiver. Then we use an EDM machine with an electrified wire that cuts the metal to the concentric center of the receiver and bolt lug with .0005” accuracy. The result: A receiver built dead-straight for supreme accuracy.

After the EDM process, AllTerra Arms machining technology sculpts the receiver interior to consistent .0005” tolerances, ensuring true Bolt-to-Bore Alignment™ and No-Fail Cycling™.

- The Bolt

Making the AllTerra Arms bolt dead-straight from a one-piece steel billet isn’t easy. It takes innovative engineering and precision machining to create a perfectly aligned bolt that locks to bench-rest tightness while also eliminating bolt binding. Our design does that, which keeps the firing pin exactly aligned to ensure a consistent, powerful center strike on the cartridge primer every time.

Another critical consideration in bolt design is lock time, which is that precious moment between squeezing the trigger and ignition of the cartridge. A shooter flinching in those milliseconds can mean the difference between hitting and missing a target at long range.

We build smarter, faster firing pins. It starts with the spring. You want it “floating” inside the bolt center, instead of “snaking” under tension and rubbing against the inner surfaces. An AllTerra Arms spring doesn’t snake. This ultimately pushes the fluted firing pin ferrule faster and provides superior cold-weather performance.

Plus, our firing pin resides within its dead-center pilot hole at all times, versus being routed through a pin pocket like other rifles (which can also slow down lock times). When you squeeze an AllTerra Arms trigger, our blazing lock time dramatically reduces the effects of accuracy-robbing flinching.

- Patented No-Fail Cycling™

If you’ve ever experienced bolt binding in a tight-tolerance precision rifle – due to brass, scraping, dirt or other debris, you know what a pain it is – especially when cycling a round for a critical follow-up shot. AllTerra Arms solved the problem.

By machining relaxed tolerances between the bolt and receiver during cycling, we send debris out of harm’s way, so it can’t jam the gun. The AllTerra Arms action has been purposely punished in intense conditions, from sub-zero ice to field filth, and it keeps on cycling. We coat the entire bolt body with Nickel Boron for added durability and more “slippery” cycling.

Plus, because an AllTerra Arms bolt, featuring our patented conical lugs, engages and lock into a patented elliptical raceway, the surfaces are literally “self-cleaning” with every cycle. The rifle transforms from a fast-action field gun to a precision bench rest rifle the moment a hot cartridge is locked down.

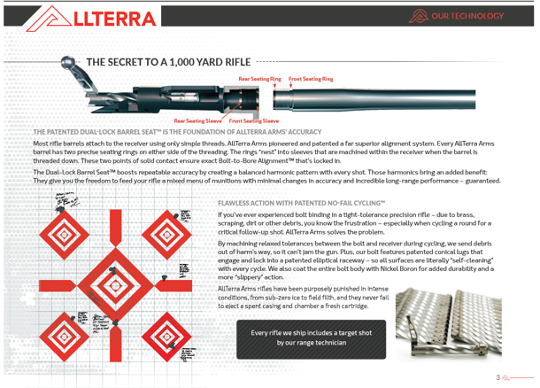

- Our Patented Dual-Lock Barrel Seat™

Most rifle barrels attach to their receivers using only 16 pitch threads. Threads are a very inaccurate way to mount a barrel, especially when super-hot loads put intense pressure on those threads. AllTerra Arms pioneered and patented a far superior alignment system.

In addition to more generous 20 pitch threads, our barrels have two precisely machined seating rings machined fore and aft of the threads. The rings “nest” into two seating sleeves machined into the receiver, and together they form the solid union between the receiver and barrel – creating a significantly reduced and balanced harmonic pattern with every shot. It’s invisible technology when looking at the finished rifle. But it’s in there, ensuring perfect barrel alignment in AllTerra Arms’ Bolt-to-Bore system.

- The Chamber

To form a rifle’s chamber, most builders only use a reaming tool. The problem is, reamers have to remove a lot of steel material and can “walk” off-line inside the barrel – causing overall misalignment. To solve this problem, AllTerra Arms begins the chambering process with a drill followed by a boring bar that always cuts concentric to the bore. It removes most of the steel for the chambering, but not all of it.

Then we come in with a chamber reamer to finish the job for the exact bullet casing geometry, with .0001” of concentric and axial tolerance to the bore. At this point in the build, our proprietary processes ensure the receiver, bolt and chamber are precisely aligned and ready to send a bullet down the bore…

- The Bore

The bullet’s journey down the bore is only as good as the barrel through which it travels. That’s why AllTerra Arms uses match-grade barrels, both cut rifled and button pulled, that are lapped to virtual perfection. Why “virtual” perfection?

Because no two barrels are ever exactly alike. And before we attach one accuracy-approved barrel to an AllTerra Arms receiver, we sometimes have to ditch others that, although excellent, just didn’t make the cut. Shooters who choose their AllTerra Arms with a carbon fiber barrel get all that same match-grade innovation wrapped inside a lightweight shroud.

- The Bore Crown

That dream buck or bull is downrange. It’s a long shot. You squeeze the trigger. Will the bullet leave the barrel properly? Even if the whole rifle is aligned, the final variable lies at the bore crown. If not perfectly perpendicular to the bore, 360-degrees, it will impart more pressure on one edge of the bullet than the other, resulting in unwanted bullet yaw.

The longer the shot, the more exponential the loss of downrange accuracy if the bullet is yawing. You want it flying just like a perfect football spiral. Therefore, every AllTerra Arms rifle is fine-tuned at the bore crown for balanced ballistics before ever being put to the task of making your lethally accurate shots.

- Innovative Stock Design

A rifle can only be accurate if the shooter executes proper form. We all know that. But did you know that many stocks actually promote poor form? And did you know that most precision rifle builders buy their stocks from another manufacturer?

At AllTerra Arms, we demand 100% control over the design, materials and craftsmanship of every stock. We build with six full layers of premium carbon fiber for strength, light weight and vibration dampening. Every aspect of the stock’s geometry is designed to put the shooter’s body and eye in harmonious alignment with the bore line. It also manages recoil beautifully by routing the energy straight back – to give your cheek a break while minimizing recoil jump and torque.

- 6-Layer Carbon Fiber: Crafted for strength, vibration dampening and a light 24-ounce base weight.

- Negative Cheek Comb: For harmonious scope-eye alignment, a solid cheek weld and minimal felt recoil.

- Above Centerline Heel: Spreads recoil straight back and evenly across the entire butt pad.

- Tilted Palm Swell: Keeps the wrist in a proper, straight posture to reduce canting and recoil torque.

- Optimal Grip-to-Trigger Reach: Puts the index pad in the ideal position for an accurate trigger squeeze.

- Subtle Beavertail Forend: Promotes a neutral, comfortable forward grip.

- Molded-In Texturing: For a slip-free grip, even when wet.

- Optional molded-in camo patterns that won’t chip or flake.

- Harmonics & Ammunition

There’s usually a substantial accuracy difference from price-point ammo to factory premiums, and another big jump when moving up to AllTerra Arms custom ammunition.

A good gunsmith can fine-tune a particular rifle for a specific cartridge load, and dial in some pretty impressive groups. But wouldn’t it be something if one gun could spit out consistent accuracy with a whole variety of ammo? AllTerra Arms can, thanks to Bolt-to-Bore Alignment™ and the concentric harmonic pattern it achieves.

Our patented, harmonics controlling, asymmetric design results in incredible accuracy with a wide range of bullets and weights for spectacular long-range performance. Even with a variety of cartridges and bullet weights accuracy remains consistent, giving hunters and shooters the freedom to feed the rifle a mixed menu of munitions. Want flat-shooting heat for long-range busting? Go for it. Need a slower, heavier round for close-range kinetic energy on a hunt? No problem. No other rifle technology controls harmonics and mitigates ammunition discrepancies like AllTerra Arms.

- The Finish Line

After meticulous engineering and manufacturing, AllTerra Arms rigorously tests the entire shooting system to weed out any component or tolerance variations that don’t measure up to the AllTerra Arms quality creed.

We break in every rifle and validate it to perform to our “as-close-as-you-can-get-to-perfect” benchmarks. Anything that doesn’t meet our rigorous standards is changed out and tested again until it’s right.

The result is the marriage of Bolt-to-Bore Alignment™ and No-Fail Cycling™ for the most accurate, field-proven, long-range rifle ever produced. Never before have these two capabilities existed in a single rifle with such a remarkable guarantee.

YOUR UNPRECEDENTED, UNCONDITIONAL MONEY-BACK ACCURACY GUARANTEE

Thanks to our patented Bolt-to-Bore Alignment™ and No-Fail Cycling™, AllTerra Arms guarantees your rifle:

- Will shoot sub .5” 3-shot groups with premium factory ammo

- Will shoot sub .25” 3-shot groups with AllTerra Arms handloads

- Will have no significant change in accuracy when shooting different bullet weights

- Will not fail to cycle smoothly in all conditions

See the full details on our industry groundbreaking unconditional, money back guarantee at www.allterraarms.com/guarantee

Designed, Engineered, & Manufactured in the USA